Our Capabilities

Fastest Time to Market | Global Supplier | Dedicated Experts

Our New York Facility is one of the country’s fastest and most efficient operations. PCI constantly assists customers in achieving the fastest time to market at the lowest total cost using our Global Supplier Base of Printed Circuit Board manufacturers. We provide outstanding PCB expert service, support, and inventory management capabilities.

Specializing In

Certified P.C. Board Factories

• All factories are ISO-9001 Approved • All factories are UL Listed • Can certify IPC-6012B CLASS 3 • Can certify IPC-6013 (RIGID/FLEX BOARDS)

Largest Board Supply Base

• A comprehensive array of PCB services • Technology to meet your requirements • Top PCB manufacturer partnerships • On-demand production scaling

Outstanding Technology

• Double-Sided Bd. through 70 Layers • Flexible and Rigid-Flex • Metal Core • Hi Temp./R.F • Specialty boards such as Rogers, Ventec, and Isola.

Fast Response Times / Delivery

• Fully managed production • Inventory Management • Fast Quotes - within 24 hours • Outstanding Lead Times

Secured and Verified Production

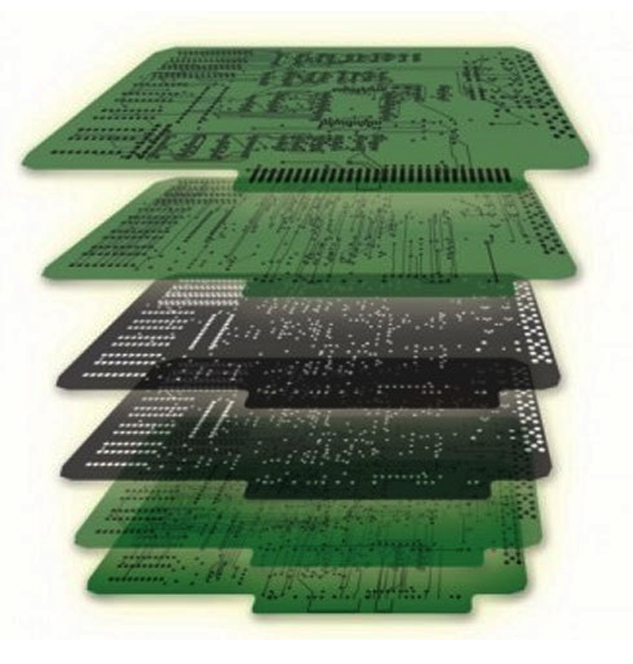

Multi-layer boards

Advanced PC Boards

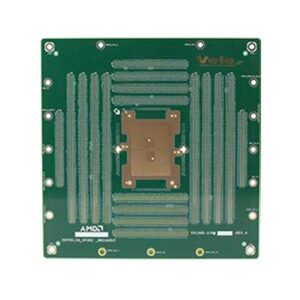

6 Layer Medical PC Boards

High Volume Production

Product Technology Development Roadmap

| PCB Type | Description | 2014 | 2015 | 2016 | Present |

|---|---|---|---|---|---|

| Conventional Rigid Board | Layers Count | >50 | 60 | 60 | 60 |

| Conventional Rigid Board | Board Thickness | 0.02 - 8.0 | 0.02 - 10.0 | 0.02 - 10.0 | 0.02 - 10.0 |

| Conventional Rigid Board | Panel Size (inch) | 22.5 X 49 | 24.5 X 49 | 24.5 X 49 | 24.5 X 49 |

| Conventional Rigid Board | Min Lin Width / Spacing for Inner Layer (mil) | 3.0 / 3.0 | 2.0 / 2.0 | 1.5 / 1.5 | 1.5 / 1.5 |

| Conventional Rigid Board | Min line Width / Spacing for Outer Layer (mil) | 3.0 / 3.0 | 2.0 / 2.0 | 1.5 / 1.5 | 1.5 / 1.5 |

| Conventional Rigid Board | Impedence tolerance control (ohms) | ± 3 (<30) ± 10% ( <30) |

± 3 (<30) ± 10% ( <30) |

± 5 (<50) ± 5% ( <50) |

± 5 (<50) ± 5% ( <50) |

| Conventional Rigid Board | Maximum PTH Aspect Ratio | 40:1 | 40:1 | 40:1 | 40:1 |

| Conventional Rigid Board | Minimum Mechanical Drill Size (mil) | 4 | 4 | 4 | 4 |

| Conventional Rigid Board | Min Spacing between via to Conductor (mil) | 3.5 | 3 | 3 | 3 |

| Conventional Rigid Board | Backdrill STUB (mil) | 10 | 6 | 6 | 6 |

| Conventional Rigid Board | Pattern to outline (mil) | ± 2 | ± 2 | ± 2 | ± 2 |

| HDI | 3 + C + 3 | M | P & M | M | 4 |

| HDI | 4 + C + 4 | M | M | M | 4 |

| HDI | Microvia Filling Plating | M | M | M | 3 |

| HDI | Minimum Microvia Hole Size (mil) | M | M | M | 3 |

| Rigid Flex Board | Layers Count / Flex Layers Count | 36/10 | 36/10 | 36/10 | 36/10 |

| Rigid Flex Board | Min Line Width / Spacing for Inner Layer (mil) | 3.0 / 3.0 | 3.0 / 3.0 | 3.0 / 3.0 | 2.0 / 2.0 |

| Rigid Flex Board | Min Line Width / Spacing for Outer Layer (mil) | 3.0 / 3.0 | 3.0 / 3.0 | 3.0 / 3.0 | 2.0 / 2.0 |

| Rigid Flex Board | Maximum PTH Aspect Ratio | 20:1 | 30:1 | 30:1 | 30:1 |

| Rigid Flex Board | Impedence Tolerance Control | 10% | 10% | 5% | 5% |

| Rigid Flex Board | Min Spacing between via to Conductor (mil) | 6 | 5.5 | 5.5 | 5.5 |

| Special Board / Process | Metal Substrate | Aluminum-substrate & copper-substrate | Aluminum-substrate & copper-substrate | Aluminum-substrate & copper-substrate | Aluminum-substrate & copper-substrate |

| Special Board / Process | Metal Substrate Depth Controlled Process Capability (mm) | ± 0.05 | ± 0.05 | ± 0.05 | ± 0.05 |

| Special Board / Process | Counter Bore Depth Controlled Capability (mm) | ± 0.10 | ± 0.10 | ± 0.10 | ± 0.10 |

| Special Board / Process | Maximum Copper Weight (OZ) | 10 | 10 | 10 | 10 |

| Special Board / Process | Heatsink, Sweat Bonding, Ceramics (DBC), Metal Buried PCB, Embedded Resistance / Embedded Capacitance, RF Hybrid Lamination, Microvia Copper Fill, Resin Fill | ||||

| Type of Surface Treatment | Flash of gold, Immersion Gold, Hard Gold, Gold Finger, HASL-LF, HASL, OSP, Immersion Tin, Immersion Silver, Soft Gold, ENIG+OSP, ENIG+G/F, Flash Gold+G/F, Immersion Silver+G/F, Immersion Tin+G/F | ||||

| Remark | R&D: Research and Development | S: Sample | P: Small Volume | M: Mass Production | ||||

For Over 40 Years Dedicated to the Highest Quality

Our team is ready to help with any project small or large! Call us 1-516-464-7770 or email [email protected]

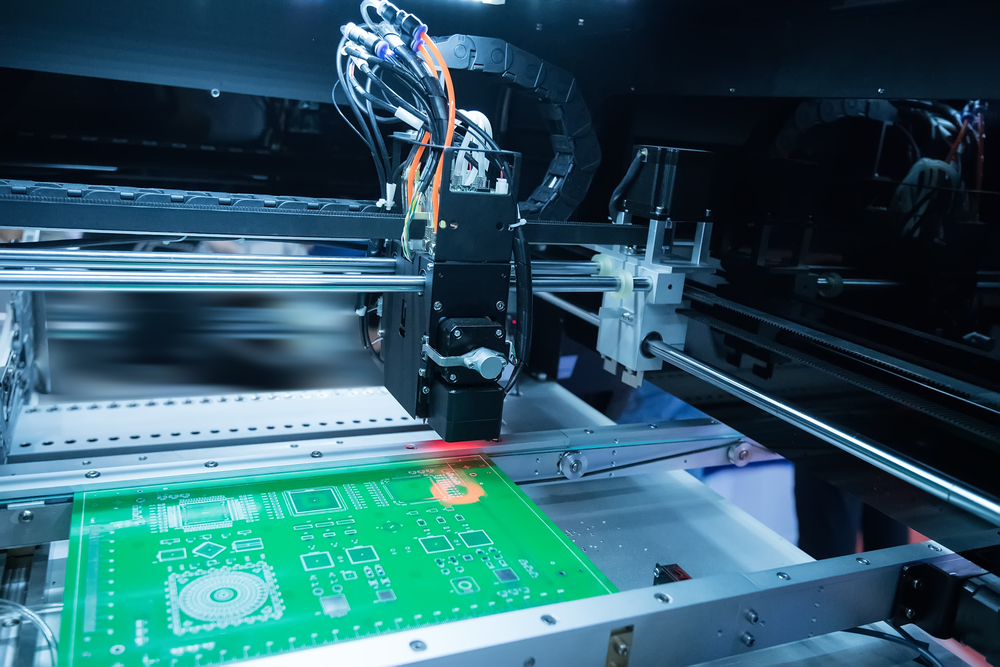

Hassle-Free Production

Precise Manufacturing

Highest Certifications and Standards